circularWOOD

How to achieve a paradigm shift towards circular economy in timber construction?

Our research project «circularWOOD» wins the German Sustainable Building Council’s (DGNB) «Sustainability Challenge 2024» in the Research category. Every year, the renowned sustainability competition honours outstanding achievements in the categories: start-up, innovation and research categories. An expert jury selected circularWOOD as the winner from among 145 submitted projects.

At the DGNB’s Sustainability Day on 18 June 2024, Dr Sonja Geier from the CCTP at the Lucerne University of Applied Sciences and Arts and Dr Sandra Schuster from the Technical University of Munich accepted the award after an exciting final round at the «Im Wizemann» venue in Stuttgart – a worthy culmination of many years of research cooperation between the CCTP and the Chair of Architecture and Timber Construction at the Technische Universität Munich.

The two project managers, Dr. Sonja Geier (CCTP, University of Applied Sciences & Arts Lucerne) and Dr. Sandra Schuster (Technische Universität München) explain their project in the video below.

Challenges

Planetary boundaries call for circular economy – So far, a number of obstacles have prevented future-oriented circular construction with wood.

No other industry consumes more energy and resources than construction. In view of planetary boundaries, the use of renewable resources and the closing of material cycles are the order of the day. Wood is a renewable resource. As a result, the material has often been excluded from the need for careful handling and high-quality reuse. Cascading use is not yet well established. Uncertainties in forest development, increasing demand for raw materials and new markets in the wood-based bio-economy have led to challenges regarding the long-term availability of wood as a resource.

Initial experience with circular timber buildings shows that a number of technical, constructive, logistical and regulatory difficulties need to be overcome. The recyclability of common construction principles is limited. In most cases, demolition is also not economically viable. Thermal utilisation is often the solution of choice. Existing frameworks and regulations in the building sector are an obstacle. In the future, additional measures need to be taken to better exploit the potential of material reuse. The growing importance of carbon accounting, the increasingly stringent requirements of the EU taxonomy and the impending obligation to create a Building Resource Passport are not specific to timber construction, but increase the pressure on policy makers and the industry.

Potential

Circular building with wood, a CO2-neutral building material, contributes to our climate protection goals. Taking into account the principles of circularity ensures the long-term availability of wood as a resource.

Wood is seen as a promising solution for the transition of construction to meet climate change targets. The industry also sees great potential in circular timber construction. Modularisation and the associated logic of assembling large-format components are favourable conditions. This makes it possible to reuse entire building elements as well as components. Material reuse instead of thermal utilisation extends the temporary carbon storage of wood. Actors in the timber construction industry have a high level of expertise in technical and constructive implementation and are actively involved in discussions on the further development of circular timber constructions. Concrete implementation is currently still at the pilot project stage: initial experience is being gathered and now needs to be used for further development.

The research project circularWOOD provides insights into the current state of implementation of the circular economy in timber construction and identifies areas for action and development in research, practice and policy.

Definition

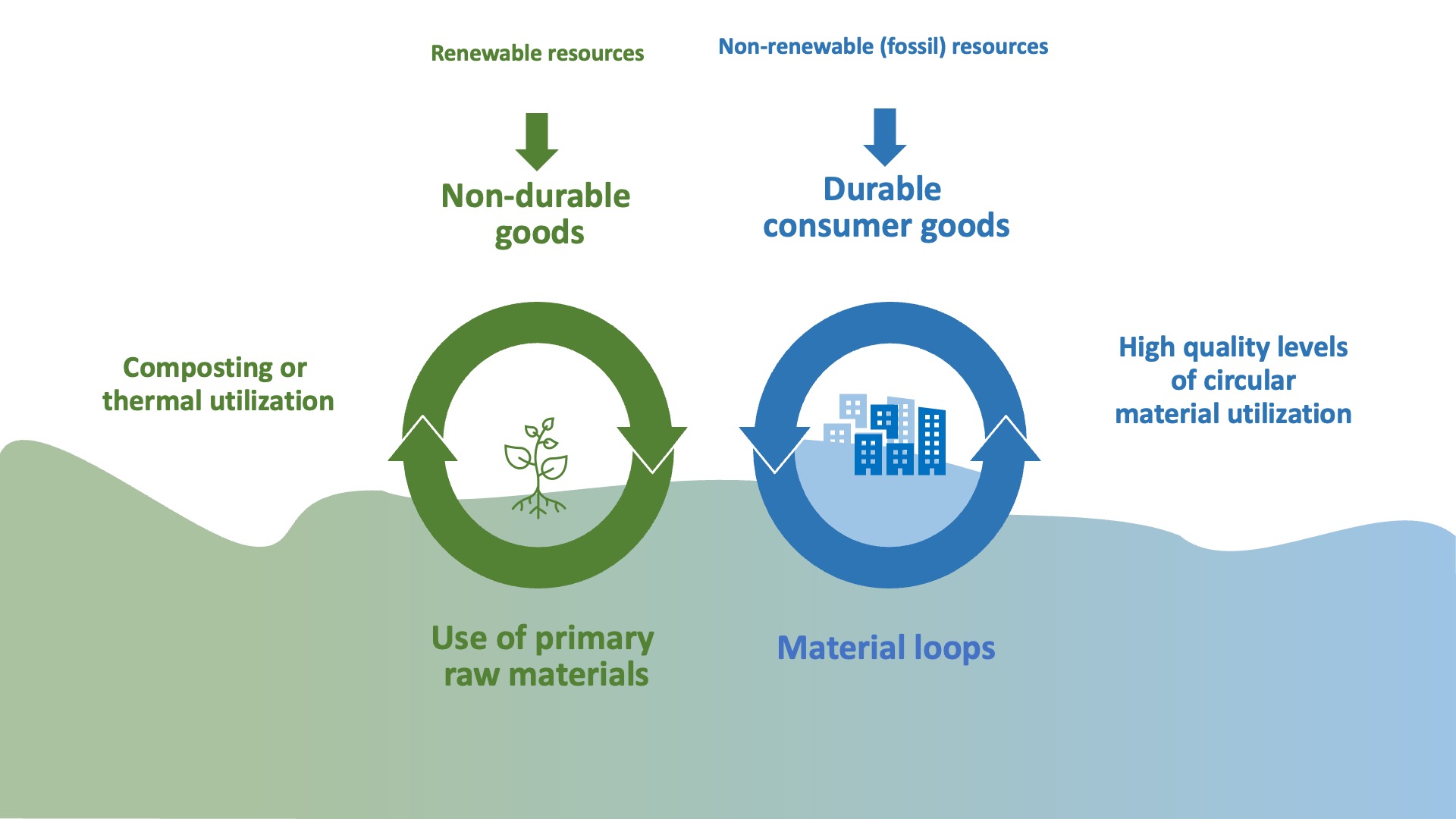

Circular construction with wood refers to the aspects of the circular economy in construction. To ensure the availability of resources, sustainable forest management and the closing of material loops are necessary.

The transition to a circular economy in timber construction represents a shift towards a new economic understanding based on material and production cycles. In the context of planetary boundaries and a renewable but exhaustible resource, it should be used in a resource-efficient and careful way according to the principles of the technical cycle in high quality reuse scenarios. Loss of quality should only occur in the context of multi-stage cascading use. Competing interests in wood use have been addressed by the premise of resource conservation through sufficiency strategies. Furthermore, a paradigm shift towards a circular economy requires a profound societal change in existing consumption and use patterns.

The need for action

A paradigm shift requires political action, research and development, and industry innovation.

Framework

The increasing importance of carbon accounting and the EU taxonomy will shape the direction towards a circular economy. It is essential to remove barriers to implementation in approval and licensing procedures. In addition, test methods for determining and defining the performance characteristics of used building components and elements need to be established and the development of technical regulations needs to be advanced.

Material and Construction

Further research and development in materials science is needed to ensure material health and longevity for reuse. Innovations in joining techniques, fasteners and connection solutions are also needed to ensure non-destructive deconstruction.

Planning and Implementation

Material- and timber-appropriate planning in the future involves consideration of building deconstruction. Responsibilities and information provision must be clearly regulated. Individual parameters must be tailored to the relevance for timber construction. Standardization must be promoted, and existing building component databases must be further developed.

Technology

With the gradual implementation of Building Information Modelling (BIM), there is potential for optimisation of design and tamper-proof long-term documentation. Further efforts are needed in modelling, interface standardisation and documentation.

Economics

There is a need to stimulate new business models for timber construction that are economically and ecologically viable, and to close material cycles. Furthermore, storage and logistics processes as well as legal aspects need to be clarified. With the increasing number of component exchanges and platforms, it is essential to develop a wood-specific and standardised representation of wood components.

Assessment

Developments in assessing the circularity of buildings are important, but not specifically tailored to timber construction. At this point, it is crucial to promote a valid evaluation of the cost effectiveness of deconstruction. This understanding will inform the further development of structures and connectors. At the same time, it can form the basis for a deconstruction cost index.

Design für Disassembly (DfD)

Design for Disassembly (DfD) lays the foundations for the deconstruction of buildings.

Design for Disassembly (DfD) is a forward-looking design and planning principle for circular buildings. DfD aims to design and construct buildings in such a way that they can be easily and preferably non-destructively disassembled, separated into clean fractions and recycled. The aim is to ensure that a large proportion of materials and building components can be transferred to high quality material reuse at the end of their life (EoL) during deconstruction. DfD provides the basis for the deconstruction of buildings. The practicalities of deconstruction determine whether deconstruction is economically viable and minimises environmental impact.

Material

The choice of materials has an impact on the circularity of a building.

The term “material” refers to the raw materials used to construct a building or product. In order to achieve circularity, it is important to select appropriate materials, taking into account the health and longevity of the material. To ensure recyclability, the purity of the material is necessary. Buildings made of materials with the same properties are called pure fractions. Non-pure materials, such as wood-based panels, have the potential for cascading use. When designing and implementing a circular building, it is important to consider these aspects carefully.

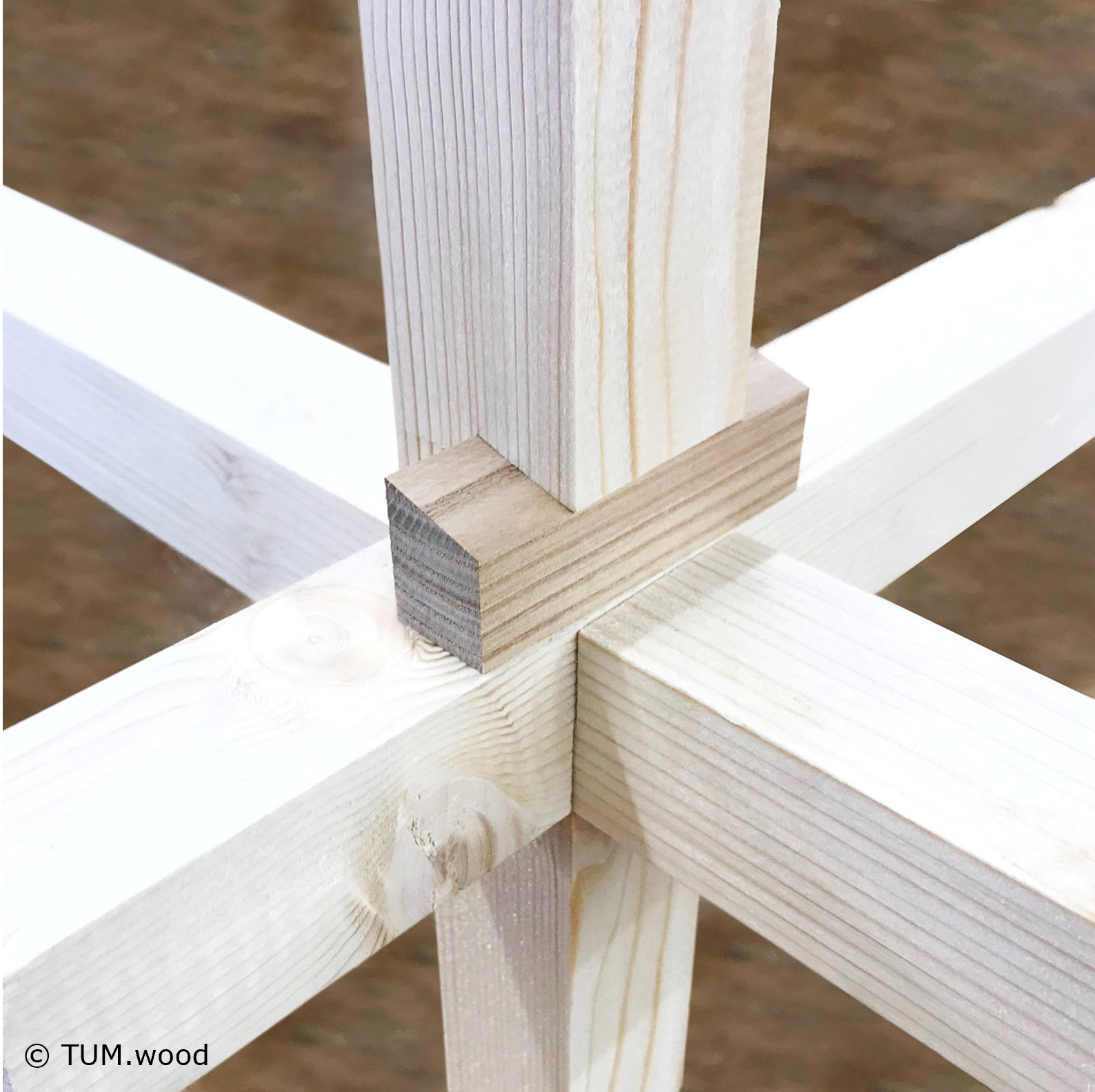

Jointing and fasteners

To enable a building to be dismantled at the end of its life (EoL) and its components reused, reversible connections and appropriate joints are required.

The multi-layered structure of components results in complex joints. To deconstruct these non-destructively, it is necessary to develop simple and standardised joints that ensure easy disassembly and separability. Disassembly describes the non-destructive separation of structural joints, while separability describes the ability to separate individual components non-destructively. Both aspects are based on simple connections, the use of appropriate fasteners and fixtures, and the avoidance of adhesives. Static bolted joints are not necessarily reversible. At this point, promising research results show new possibilities. The focus on wood-wood connections and the high precision of computer-controlled prefabrication also demonstrate the potential of timber construction to meet the requirements of circular building practices.

Organization

The research project circularWOOD is a collaboration between the Chair of Architecture and Timber Construction at the Technical University of Munich (TUM) and the Competence Centre Typology & Planning in Architecture (CCTP) at the Lucerne University of Applied Sciences and Arts. The project focused on the circular economy in timber construction in Germany and Switzerland. The project was funded by the Federal Institute for Research on Building, Urban Affairs and Spatial Development (BBSR) on behalf of the Federal Ministry of Housing, Urban Development and Construction (BMWSB) from the Future Building Innovation Programme.

Duration: March 2021 – February 2023

Links and Downloads

- Link to the Future Building Project Website

- Link to the circularWOOD Project Website

- Download Final Report BBSR

- Link to the Transfer Report

Contact

Dr. Sonja Geier

Project Manager

Competence Centre Typology & Planning in Architecture (CCTP)

sonja.geier@hslu.ch