Experimental and Numerical Investigation of Powder Material inside Additive Manufactured Particle Dampers

Gian Hauenstein

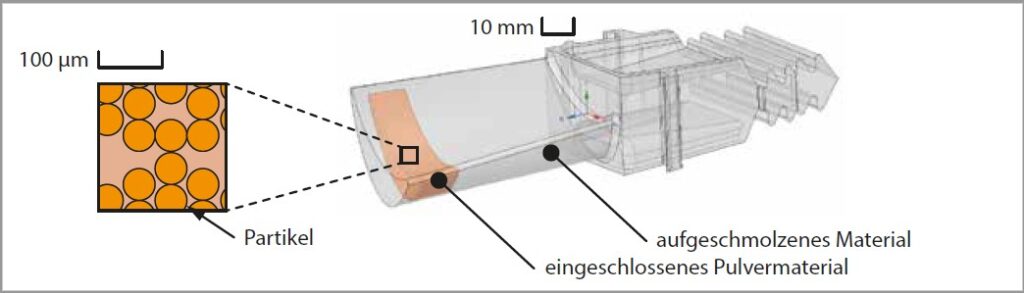

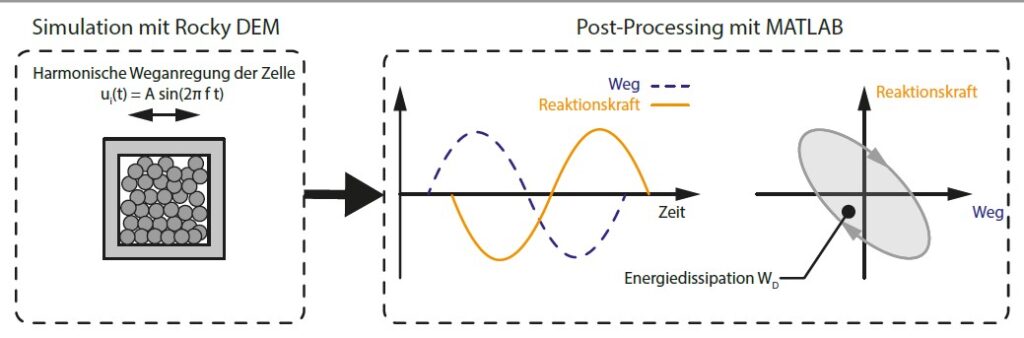

Particle dampers are a promising approach for passive reduction of vibrations. With additive manufacturing, it is possible to manufacture parts with embedded powder cavities. The goal of this thesis is to determine the dynamic behavior of the internal powder in an additive manufactured particle damper. The research questions are: • How can the energy dissipation of powder be characterized? • In addition, what are the main dependencies for the product development of additive manufactured particle dampers? In this thesis, the dynamic behavior of the stainless steel CL 20ES powder is modelled with the Discrete Element Method, which is a numerical method for simulation of particle motions and particle interactions. Due to the powder material used, which has particle sizes in the micrometer range and a high number of particles per volume, it is only possible to perform this investigation on scaled cavities in the millimeter range. The dynamic behavior of the powder is determined under harmonic base excitation of the cavity. This work examines the influence of different cavity sizes, cavity shapes, excitation amplitudes and frequencies on the energy dissipation.

Studienbetreuer: Ralf Baumann

Preisträger: NAFEMS Award (1. Platz)