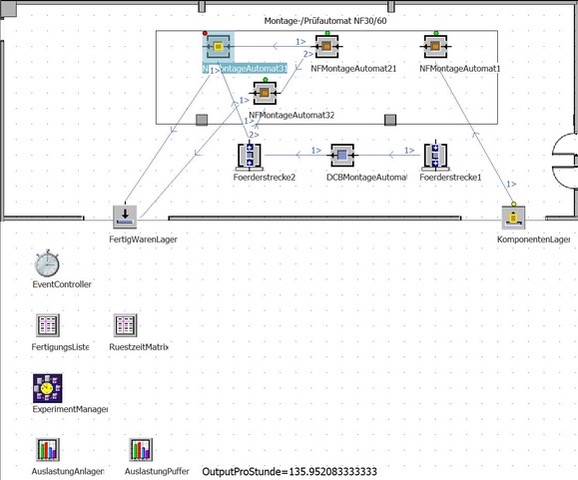

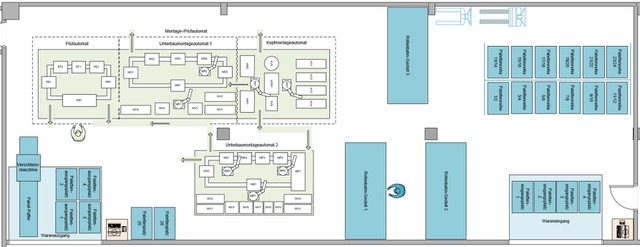

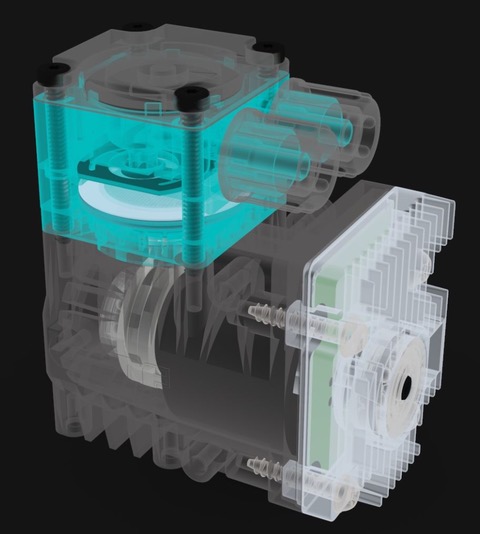

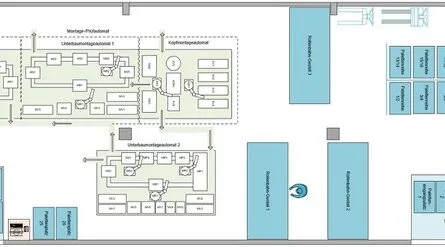

The KNF Flodos AG, a manufacturer of liquid diaphragm pumps, is increasingly exposed to competition. Buyers of large quantities are questioning the currently pursued pricing strategy. Measures are therefore being taken to ensure that the company can continue to defend its market position effectively. The products are characterized by a high degree of specialization and configurations tailored precisely to customer requirements. A new product will combine these unique selling points with a cost-efficient pump design. In addition, the two best-selling products are to be assembled automatically in a cost-efficient manner in the future. The goal of the master thesis was to define an automation strategy, which addresses the current challenges of the company. This included not only the demonstration of the feasibility of different assembly, logistics and personnel concepts, but the resulting maintenance issues and the definition of the requirement specifications for implementation. The approach required the use of simulation software (Siemens Tecnomatix Plant Simulation), intensive study of technical literature and carrying out expert surveys.

Studienbetreuer-in: Fabio Mercandetti